“`html

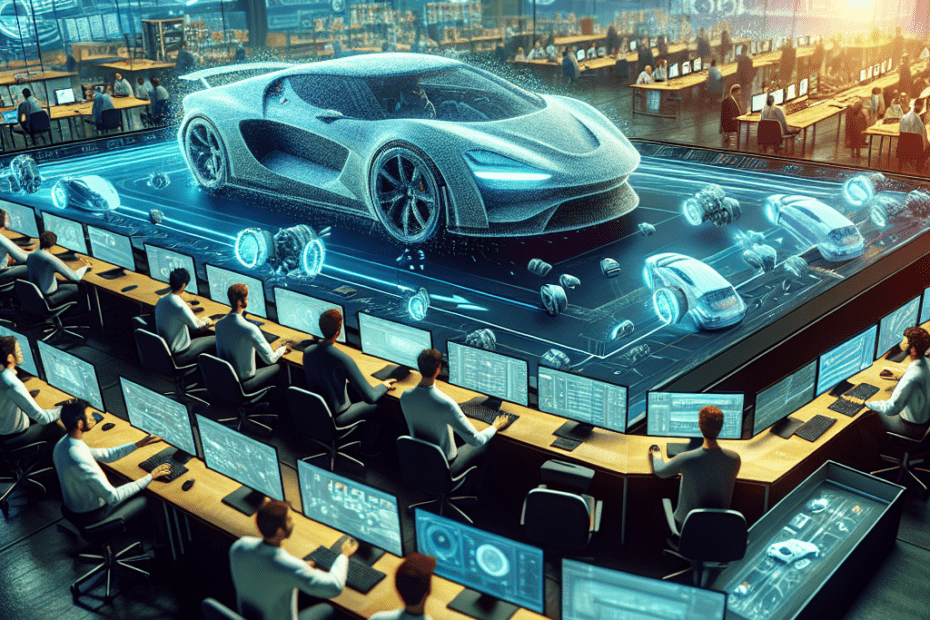

In recent years, the automotive industry has experienced significant transformations driven by technological advancements. They are now embracing virtual car testing and simulation as a key part of their vehicle development process. With rapid digital innovation, engineers can simulate entire car environments, leading to more efficient, safer, and cost-effective production processes. This technological evolution is paving the way for modern vehicle testing, reshaping how new models are brought to life.

One of the major advantages of virtual car testing is cost reduction. Traditional testing methods often require physical prototypes, which are both time-consuming and costly to produce. Virtual simulation mitigates these expenses, allowing manufacturers to test vehicles under various conditions without the actual need for physical prototypes. According to a study by Forbes (2022), companies can save up to 30% on development costs with simulation-based testing.

Moreover, virtual car testing enhances safety. In a virtual environment, vehicle components can be subjected to extreme conditions without any risk of damage or failure. This thorough testing process ensures that any potential defects are addressed before a car goes into production. For instance, the automotive safety company, ANSYS, reports a 25% increase in efficiency concerning safety testing when virtual simulations are employed.

Another significant element of virtual testing is the improvement in the design process. Engineers and designers can experiment with a broader array of designs and configurations, thanks to the flexibility of simulation software. This flexibility leads to better-optimized designs and innovations, allowing manufacturers to experiment with novel elements such as new materials or aerodynamic structures without the high costs typically associated with physical experimentation.

Growth in Virtual Simulations

The use of virtual simulations is rapidly growing, with market studies indicating a substantial increase in its adoption. The global automotive simulation market is projected to reach $3 billion by 2025, growing at a compound annual growth rate (CAGR) of 11.3% according to Market Research Future (2023). This growth is propelled by advancements in 3D modeling, machine learning, and real-time analytics, which together provide more accurate and detailed simulations.

Additionally, regulatory bodies are recognizing the value of virtual testing in meeting safety and environmental standards. Many countries now support or even mandate virtual testing as a preliminary step in vehicle certification processes. This compliance with regulations helps manufacturers meet stringent global safety standards while also reducing the environmental impact by minimizing material waste during prototype testing.

Challenges and Considerations

While virtual car testing offers numerous benefits, it is not without challenges. One significant concern is the technology’s initial cost and the need for skilled personnel to operate complex software systems. Although the long-term savings are significant, the upfront investment can be a barrier for smaller companies. Still, they find that investing in virtual simulations becomes indispensable over time.

Moreover, the accuracy of simulations largely depends on the data quality input into these systems. Inaccurate or incomplete data can lead to unreliable results, impacting the reliability of real-world application predictions. Therefore, maintaining high data standards and regular software updates is crucial in this evolving field.

Table: Benefits and Challenges of Virtual Car Testing

| Benefits | Challenges |

|---|---|

| Cost Reduction | High Initial Costs |

| Enhanced Safety | Data Quality Requirements |

| Improved Design Flexibility | Need for Skilled Personnel |

| Regulatory Compliance | Complex Software |

Key Takeaways

- Virtual car testing helps in reducing costs, enhancing safety, and improving design processes.

- The demand for automotive simulation is growing rapidly, with a projected market value of $3 billion by 2025.

- While challenges exist such as high initial costs and data quality concerns, the advantages make virtual simulations a valuable tool in the automotive industry.

- Regulatory bodies are increasingly recognizing virtual testing as an efficient way to adhere to safety and environmental standards.

FAQ

- What is virtual car testing?

Virtual car testing involves the use of computer simulations to test vehicle designs and components before they are physically manufactured.

- How do virtual simulations help reduce costs?

By lessening the need for physical prototypes, companies can save money on materials and production efforts, lowering overall development costs.

- Are virtual simulations reliable for vehicle safety testing?

Yes, virtual simulations can reliably test vehicle safety by subjecting components to extreme conditions without risking physical harm.

- What are the main challenges of virtual car testing?

The main challenges include the high initial cost of technology, the complexity of the software, and the necessity for precise data quality.

- Why are regulatory bodies supporting virtual testing?

Regulatory bodies support virtual testing because it allows manufacturers to adhere to strict safety and environmental standards efficiently.

“`